GRP is sometimes referred to as; glass reinforced polyester, fiberglass, glass-fiber reinforced plastic (GFRP), fiber reinforced plastic (FRP) or fiber reinforced polymer (FRP). GRP can be mass produced or built-up by hand, and after curing, forms a complex matrix of plastic and glass fiber. The composite properties of high-strength glass fiber and highly-resilient plastic, make GRP strong, lightweight and weather- and corrosion-resistant. It can also be manufactured to be fire retardant.

GRC is widely and reliably used in architecture, building, engineering applications. Moreover, complex forms, decorative materials and a whole building can be produced with the aid of digital technologies. GFRC is also a very important resource which includes self–cleaning environmentally friendly panels, easily dyeable surfaces, and high-performance concrete applications for over 40 years. GFRC can be produced as thin as 6 mm so their weight is much less than traditional pre–cast concrete products.

GRG wall panel is made essentially of gypsum plaster reinforced with glass fibers. It provides a new method of building construction in fast track, fully utilizing the benefits of prefabricated, light weight large panels with modular cavities and time tested, conventional cast-in-situ constructional use of concrete and steel reinforcement. GRG is lighter than traditional gypsum and can be formed to a better detail.

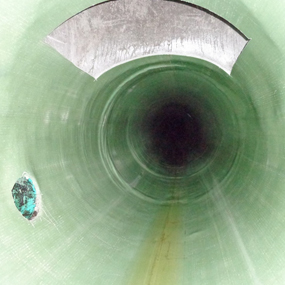

Yeung’s FIBERTECH pipeline rehabilitation experts are working with municipal clients to meet their pipeline maintenance needs. Rehabilitation is a proven approach to extending the service life of pipelines with a significantly reduced impact over replacement.